Project Overview:

This project aims to treat the printing and dyeing wastewater discharged by a printing and dyeing enterprise in Tianjin. The wastewater mainly comes from the processes of printing and dyeing rinsing, desizing, and bleaching, and contains a large amount of pollutants such as dyes, auxiliaries, and fiber impurities. The characteristics of wastewater are high organic content, poor biodegradability, deep color, COD concentration of about 5000mg/L, and pH value between 6-7. The project design has a processing capacity of 4000 cubic meters per day and requires continuous 24-hour operation, with an average processing capacity of 170 cubic meters per hour. The treated wastewater must meet the third level standard of the Tianjin Municipal Comprehensive Wastewater Discharge Standard.

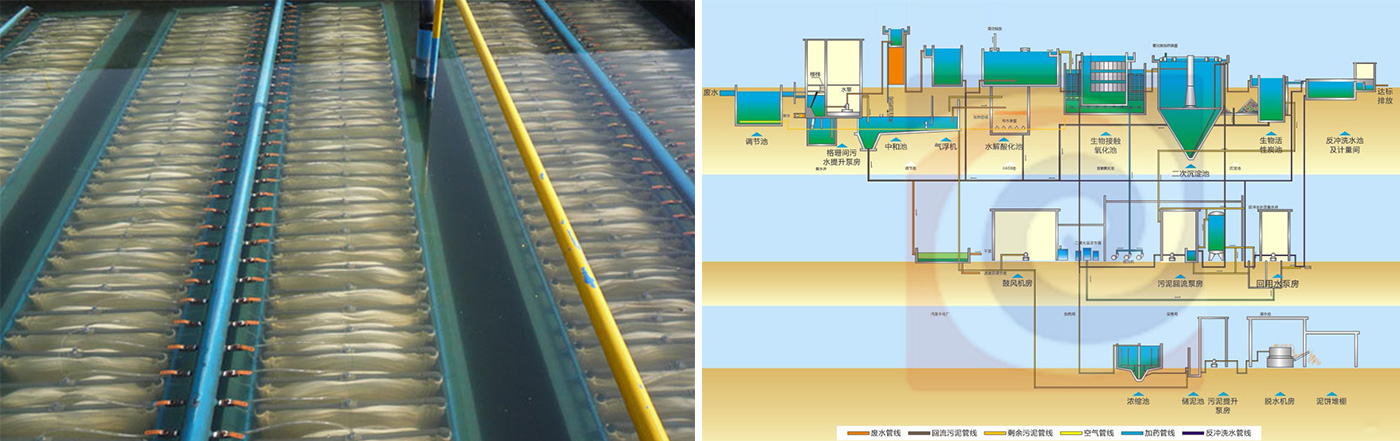

Processing technology:

The project adopts the main process of “microelectrolysis coagulation precipitation hydrolysis acidification EHBR (high-efficiency bioreactor)”. Among them, the coagulation and sedimentation process is an important step in removing suspended solids, colloids, and partially dissolved organic matter from wastewater. At this stage, high-quality polyaluminum chloride (PAC) and polyacrylamide (PAM) produced by YuXinHuan were introduced as coagulants and coagulants.

Application of Yuxinhuan products:

Polyaluminum chloride (PAC): professionally manufactured by YuXinHuan, it is an efficient inorganic coagulant. Its unique bridging, net capture, and electrical neutralization capabilities can quickly condense small particles and colloids in wastewater, forming easily separable flocs, effectively reducing the turbidity and suspended solids content of wastewater.

Polyacrylamide (PAM): As a coagulant aid provided by YuXinHuan, PAM enhances the coagulation effect of PAC through the adsorption bridging effect of its polymer chains, promotes the rapid formation and sedimentation of flocs, and improves the efficiency of wastewater treatment and effluent quality.

Engineering operation effect:

After the treatment of “microelectrolysis coagulation precipitation hydrolysis acidification EHBR” process, the organic matter in the wastewater is effectively degraded, the color is significantly reduced, and the effluent quality is stable and meets the indirect discharge standard of textile dyeing and finishing industry water pollutants (GB 4287-2012). The total operating cost of the project is 3.26 yuan/ton, with a total investment of approximately 1 million yuan. The successful implementation of this project not only improved the environmental protection level of the enterprise, but also achieved the resource utilization of wastewater, making a positive contribution to the sustainable development and environmental protection of the enterprise.

Author: YuXinHuan®

WhatsApp:+86 19037152650

Email:xinhuan@xhwtm.com